Product features

Here you can see examples of some of the most important features in our products. For further information - contact us and book a demonstration.

CadConnect features

Avoid double keying your CAD data

CadConnect imports product structures directly into Business Central so items, components, and BOMs don’t require manual entry. This saves time and reduces errors.

Handle quotes without item setup first

Sales BOMs and specifications can be built in CadConnect before items are created in Business Central . When a quote becomes an order, master data can be created directly from the structure.

Create variants from existing products

CadConnect allows Business Central product data to be used for creating variants. Starting from an existing product, components, quantities, or structure can be adjusted - giving a fast and controlled process.

Manage product versions the BC way

CadConnect supports versioning of BOMs and items in line with Business Centrals standard features. This provides better control during ongoing product changes.

ItemPlanning features

Projected inventory development

ItemPlanning shows the projected inventory development for each item, so planners can clearly see when a shortage will occur and what drives inventory changes over time.

Early identification of shortages

The app provides a clear view of upcoming material shortages across sales, production, and assembly.

Shortages are identified early, so they can be addressed immediately.

Know when you can deliver

ItemPlanning shows when materials are expected to be available and when an item can be completed. This provides a realistic basis for responding to customers and planning deliveries.

Focus on critical items

The built-in Critical Items feature highlights items that require special attention, both in the short and longer term, allowing planners to react quickly and maintain stable production.

MakeToOrder features

Automatic date changes across the entire production structure

MakeToOrder updates dates across the main order and all related orders, keeping the entire production structure aligned with the revised plan.

ShopFloor MES features

Adapting the system to your needs

Easily configure ShopFloor MES to match your specific requirements, processes, use cases, and production needs.

Change production order sequence

Orders can be expedited or postponed from the predefined date sequence according to the planner's preferences.

Multi-resource job assignment

Reduce lead time by assigning multiple resources for parallel execution as needed.

Flexible job execution across orders

Run multiple jobs across production orders, operators, and machines with automatic time and cost tracking.

Controlling production capacity

ShopFloor Planning gives planners visibility into the current and future load on machines and work centers.

Digital order processing information

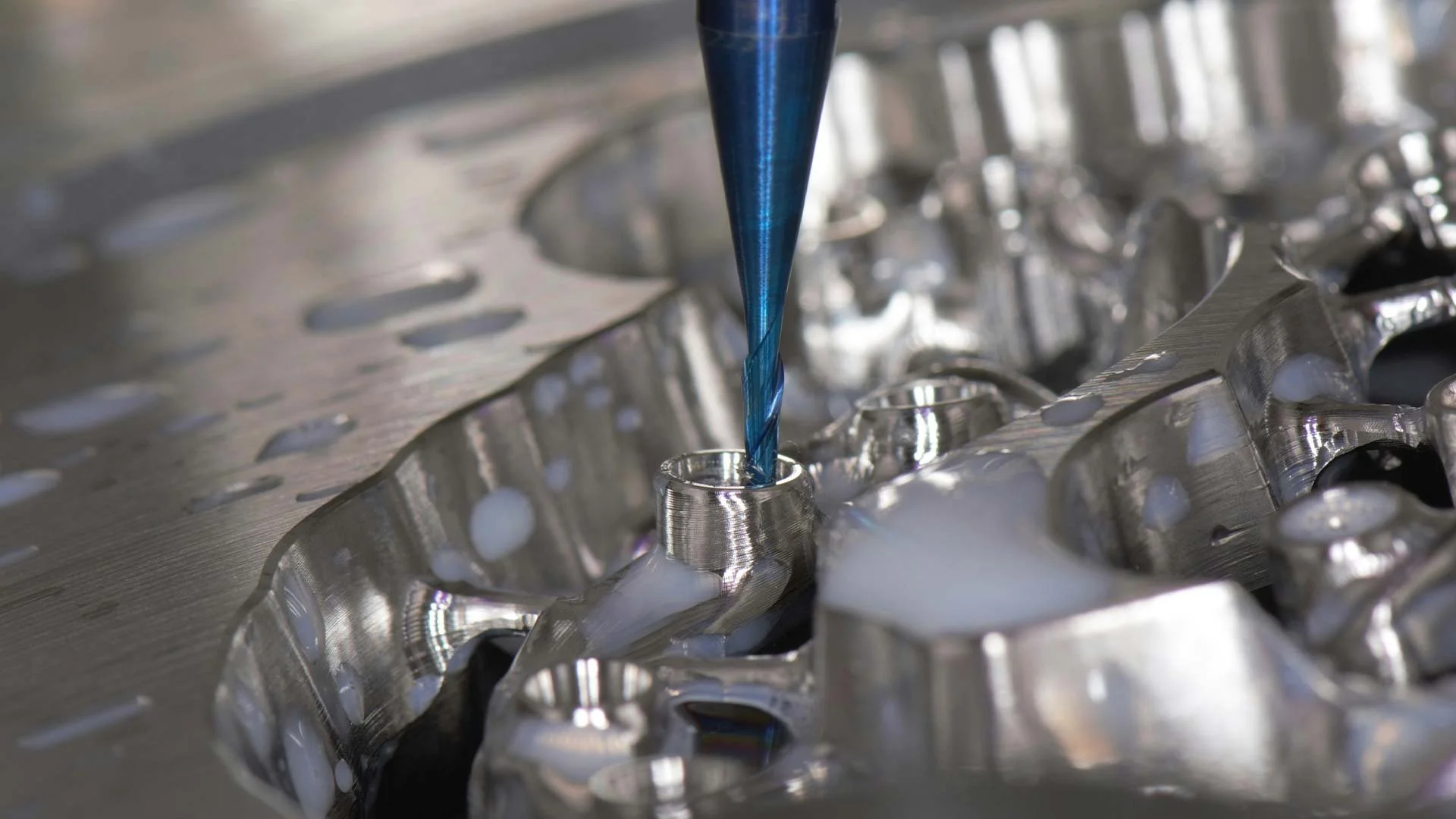

The operator has all necessary instructions, process sheets, tooling, and quality information available on the display.

Planner shop floor control

The ShopFloor system is split into two areas: the planner's workspace and the operator's execution area - both fully integrated.